loading...

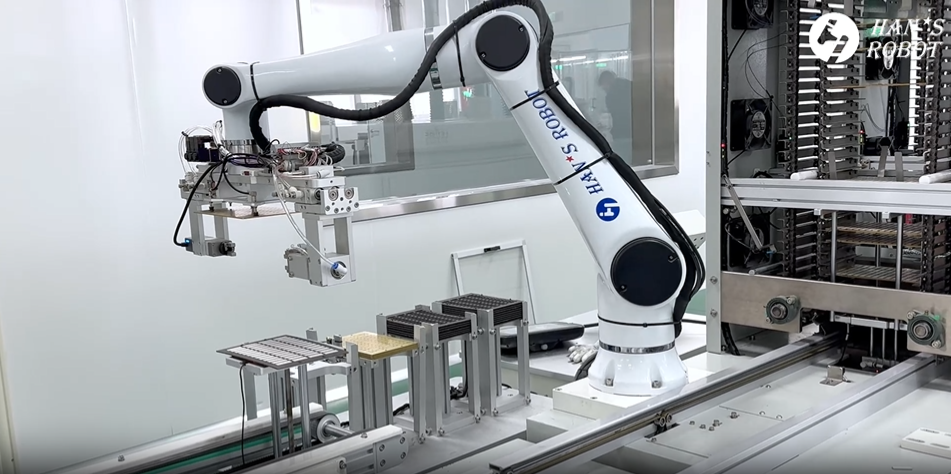

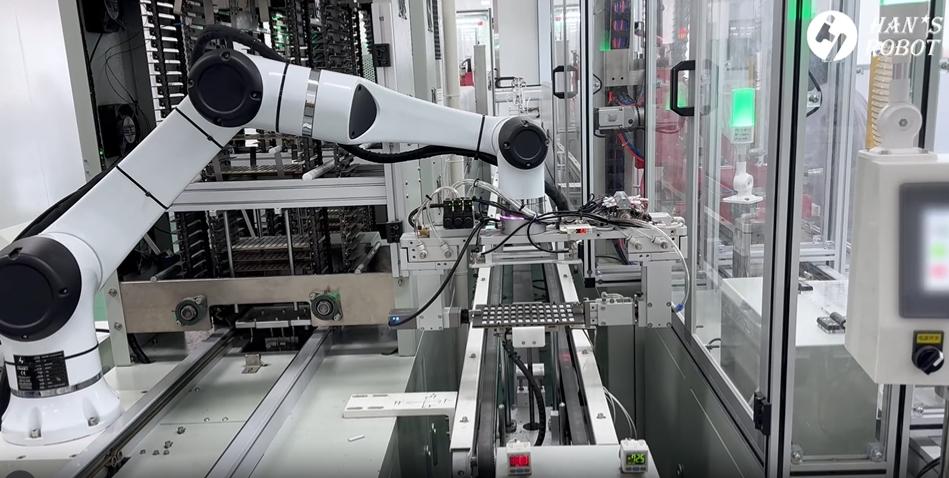

Collaborative robots are effective robot workers. They can safely work alongside human operators in a shared workspace. Cobots have sensors and controls that automatically detect humans and stop immediately if needed. They are widely used for material handling tasks like CNC loading and unloading due to their precise and repetitive actions. Using a collaborative robot for these tasks can help address various challenges. It also improves safety, efficiency, and productivity.

The constant motions risk straining muscles and joints. Examples include strains on the back and shoulders. Wrists and neck may suffer pain as well. Over time, this repetitive strain can lead to painful and debilitating injuries.

Some materials might be hot, sharp, or toxic. It is difficult for people to interact with these safely, putting their well-being and mental health at serious risk.

To minimize fatigue and injuries while meeting high throughput demands, frequent shift changes and additional staffing are often necessary. However, increased workforce can lead to higher costs and reduced profit margins.

Prolonged physical exertion causes tiredness, which compromises safety and efficiency towards the end of a shift. Productivity declines as workers slow down to prevent strains, hurting overall performance.

As humans get tired, distractions or lack of concentration during loading and unloading can increase the risk of accidents such as dropped items, collision of equipment, etc. This can damage expensive machinery.

A collaborative robot has many safety features. These include torque sensors, force-limiting controls, and vision systems to detect nearby humans. This allows safe cooperation without the need for clunky guards (such as the safety fencing for industrial robots). Workers are protected from ergonomic hazards and dangerous payloads.

A collaborative robot can operate for longer hours compared to people. It lifts items precisely and rapidly, increasing throughput. Pairing humans with cobots for complementary tasks boosts overall productivity.

A cobot solution follows repeatable motions precisely thanks to its mechanical design and programming. Every item picked or placed is done so with consistent accuracy of up to ±0.02mm, minimizing defects from human error.

A collaborative robot can be quickly reprogrammed to new loading and unloading patterns and handle diverse payloads with ease. This allows operations adapt fast to production changes without disruption.

Utilizing collaborative robot models from a leading manufacturer for repetitive loading and unloading operations is beneficial. It can help companies overcome many challenges of labor-intensive manual work. Cobots improve workplace safety, boost productivity through 24/7 operation without fatigue, and lower long-term costs. They are precisely suited for material handling processes.

At Han’s Robot, we offer reliable collaborative robots and automation solutions that are safe, versatile, and customized. Browse our website to explore all our offerings and partner with us to streamline your production.