loading...

Flexible manufacturing has gained much importance in the 3C (Computer, Communication, and Consumer Electronics) industry. This is due to the rapid iteration of products like smartphones, tablets, and laptops. Factories need to be able to quickly adjust their production lines to launch new products. Collaborative robots or ‘cobots’ provide a solution for them to attain such flexible manufacturing.

Collaborative robots bring several key benefits to manufacturing. These include:

1. Consistent and Accurate

Cobots ensure consistent accuracy in repetitive tasks. They meet tight tolerances demanded in 3C device production. Running the same program repeatedly, they precisely execute motions with minimal deviation.

2. Flexible and Mobile

A collaborative robot is highly adaptable to changes in production lines. It can be easily moved around as needed if equipped with wheels or mobile bases. This allows rapid line reconfiguration for new products.

3. Fast Programming and Deployment

Programming and deploying cobots takes much less time than large industrial robots. The process can be completed within minutes rather than hours or days. This cuts downtime between product transitions. New products can be introduced much faster thanks to collaborative robots.

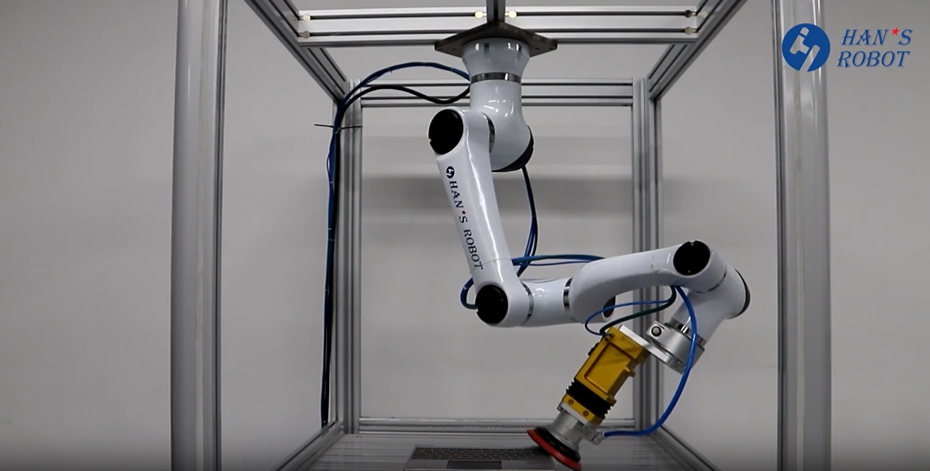

Cobots play an increasingly important role in production lines within the fast-changing 3C sector. They support workers with repetitive tasks. For instance, various models by the cobot company Han’s Robot provide flexible and custom solutions. These include:

1. Thermistor Tray Loading and Unloading

Han’s Robot’s E10 collaborative robot can be used for loading and unloading thermistor trays. It uses its rotary electric gripper to accurately replace thermistor trays. Not only does it reduce the risks associated with manual work in high-temperature environments, but it also prevents workers from being exposed to chemical fumes for extended periods.

2. Laptop Keyboard Grinding

For laptop keyboard surface treatment, our Elfin cobot is used to conduct precision grinding. In traditional manual grinding, there are drawbacks like dust, noise, etc. By automating the grinding process with our Elfin robot, we have eliminated these issues. Our Elfin cobot also improves work efficiency thanks to its fast and accurate operation.

3. Electronic Component Soldering

Our E05 collaborative robot performs complicated soldering of integrated circuits together with auxiliary machines. The pass rate has increased from 60% to 95%. This translates to lowered costs and boosted productivity for manufacturers.

4. Display Panel Gluing

Collaborative robots like our E10-L are used for gluing touch panels on 3C devices. Moving steadily without jittering, cobots ensure uniform glue distribution. E10-L’s six-axis cobot arm can glue complex curved panels easily, hence meeting the demands of customized designs in smartphones.

5. Power Adapter Screwing

By integrating electric screwdrivers and screw feeders, cobots fully automate screw tightening in IT hardware assembly. This enhances precision while freeing up workers for other value-added roles. Our advanced cobots handle the full workflow from feeding to tightening. They help achieve optimal efficiency through continuous operation.

The integration of cobots into 3C production lines benefits workers by automating repetitive tasks. By taking over exerting tasks like continuously picking and placing electronic components, collaborative robots allow workers to focus their skills elsewhere. Workers no longer have to endure physically stressful tasks or risk harm from production line hazards. This improves both work efficiency and employee wellness.

Cobots also provide opportunities for workers to engage in more cognitive work. Rather than performing automated chores, workers can spend time on vital tasks requiring human thought. These include product quality checks, equipment maintenance, and data monitoring.

Collaborative robots are enabling flexible and efficient modern manufacturing in the fast-paced 3C industry. Their applications like parts handling, inspection, assembly, and material insertion are invaluable. The leading cobot manufacturer Han’s Robot provides reliable cobot solutions tailored for various needs. Our customer-oriented approach helps factories maximize productivity while maintaining high quality. Browse our website to learn more about our collaborative robot solutions.